Recorded Memories

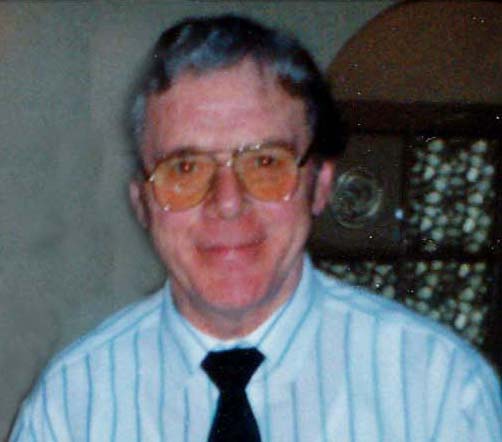

Harold Cash

Interviews. October 2000 & 2001.

‘The German machines were way in front of anything that we

could produce in this country

at that time (mid to late 1970s)…

the machinery were built to perfection’

Harold recalls the one and only outing he and Claire went on, when he worked at Moore, Eady and Murcott, Goode in about 1949 - 250

Employees were taken to Blackpool by train and it rained all day but they had a brilliant time. He also recalls the factory cricket and football competitions which took place commenting that there was a lot of rivalry between the various factories. Claire spoke about the wonderful dinner-dances organised by Fine Jersey to the Grand Hotel in Leicester - ‘a real dressing up occasion’. It was at one of these occasions where Harold had to give a speech thanking the MD - he took this very seriously and joined the Cedars Speakers Club in order to perfect his speech and also presented the MD with a pewter replica of the company logo.

During the recorded memories Harold looks at photos taken at various hosiery and knitwear factories and also a brochure. He describes working in an alley with about 30 circular knitting machines - always something to do. The B5s he felt were the ‘mainstay’ of the hosiery up until late 1950s when more modern machinery started being made. The job of a knitter has changed over the years - the knitter becoming more of a supervisor of his machinery. Machinery generated a huge amount of heat and this was even worse during the summer months. In 1976, while working at Fine Jersey, Harold was one of six people to be sent on an electronics training course to the Morat factory in Germany - a huge factory employing 3-4000 people. The Morat and Myer machines, he felt, were ‘way in front of anything we could produce’.

While looking at Opportunities with Atkins Bros Harold gives a technical description of the American Reading 100 fully fashioned knitting machine, and describes it as a ‘superb machine’. He learned all the ‘tricks of the trade’ while working as an apprentice with the two elderly gentlemen. He learned to ‘plyer’ which was an integral part of a fully fashioned knitter’s job - each needle had to be perfectly straight, if the bearded needle was crimped this resulted in missed stitches, stating that, ‘I became a very, very proficient needle plyerer, one of my main assets’. At the time of the interview he still had his plyers. The Reading 100 had 24 heads and made 24 stockings at once taking about ½ hour. He gives an excellent technical description of the Reading and explains that at this time the ‘old English foot’ was produced on a separate machine - a ‘running-on’ machine operated by girls. The foot was then attached to the leg by the knitter and the flat stocking was taken to be seamed. The knitter would operate one of these machines. With the Mellor Bromley-4-at-once, however, a knitter would operate six machines. During WWII ladies often did the knitting - there was a great demand for mercerised-type stockings.

Harold remembers, men working on circular knitting machines, when nylon first came out, they had to wear black gloves and one man forgot to take his gloves off and the needle snagged the glove taking his finger with the machine…

|

|

|

|

|